Unisynth Group Of Companies

Founded in 1981 by Mr. Purushottam Sharma, Unisynth Group of Companies comprises of,

- Unisynth Chemicals

- Unilex Colours & Chemicals Ltd.

- Unisynth Oil Refinery India Ltd.

- Chemi Udyog

Under the brand name of UNISYNTH, are the ISO 9001 : 2008 certified companies. Unisynth Group is a leading manufacturer of raw materials for cosmetic, soap & detergent, Personal and health care products like Petroleum Jelly & Mineral Oil along with a unit for colorants based in India. The factories are located in the western as well as north eastern parts of India. Due to the outstanding quality of our products and the solid reliability we provide to our customers, we have positioned ourselves as a dependable player in the global cosmetic, soap detergent & colourants markets.

In order to achieve its vision, Unisynth has set well defined objectives including maximizing efficiency, focusing on customer's needs, delivering high quality products, maximizing efficiency, focusing on customer's needs delivering high quality products, optimizing output, maintaining the highest degree of safety and protecting the environment

WHY UNISYNTH

- Consistency in product is assured by our in-house Quality Assurance Department

- Custom made products as required by the specific end users developed by our sophisticated Research & Development Department.

- Technical Support Pre & Post Sales.

- Prompt Deliveries.

- Different packaging as required by the customers.

- Support for new products / application development.

- A government recognized export house.

Management

| Mr. Purushottan Sharma Chairman Chartered Accountant |

||

| Mr. Aditya Sharma Director (Technical) M.Sc |

Mr. Manoj Sharma Director (Purchase & Finance) B.Com |

|

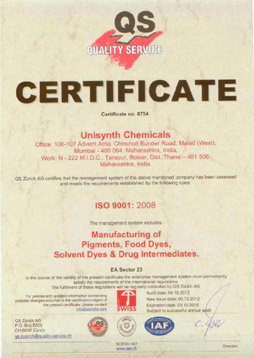

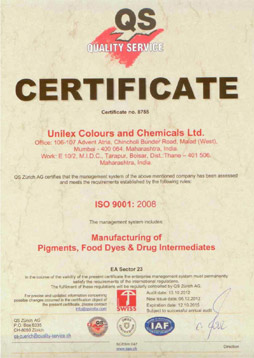

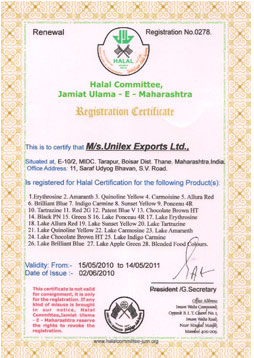

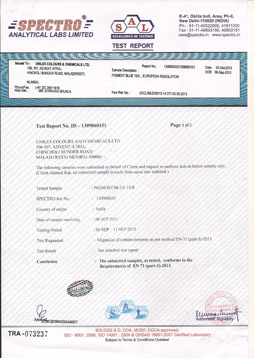

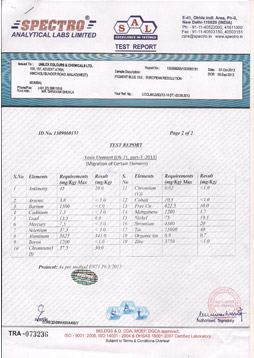

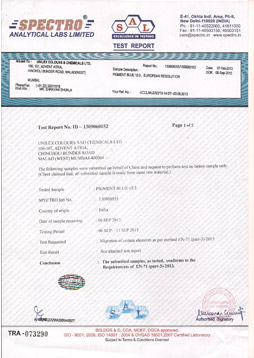

ISO Certifications

Certification

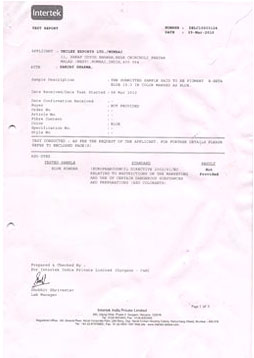

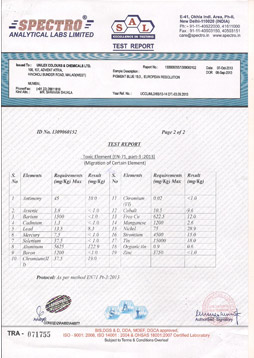

EN 71:3 Certificates for Heavy Metal in Pigments

EXPORTS

The company exports more than 90% of its Production.

MARKETING STRATEGIES

The company monitors market demand and devices production plans to meet demands generated in global market. Its stepwise analysis of raw materials for each batch results in a superior good quality of finished product. The input cost is rigorously controlled to make its cost effective in the competitive market.

QUALITY DEVLOPMENT AND EXCELLENCE

Quality control begins even before the material enters the factory.All raw materials, batch process samples and finished goods are subjected to rigorous testing. This is done by the help of qualified and experienced team of chemist and latest testing apparatus namely colour matching spectrophotometers, HPLC, Atomic Absorption spectrophotometer,High precise analytical etc...

The company's hidden strength lies in the zeal of its people. There is a desire to improve product quality and meet growing needs of the industries.

At Unisynth we are committed to ever continuing improvement to strive for excellence in all areas. Goal is not product quality but also support, services and timely deliveries.

R&D

The company is having its own R&D facility and entire product development is through R & D efforts. Relation Institutes for reference is also established.

ENVIROMENT CONTROL

Primary effluent treatment plant forms a part of effluent control system coupled with a full fledged effluent treatment plant of C.E.T.P. (TIMA) to take care of our effluents to standard limits regulated by law. Safety programme plan is part of our inbuilt culture.

MANPOWER

The company is having trained staff & workers. The present strength is 80. The industrial relations are smooth & cordial throughout.

HEALTH AND SAFETY POLICY

Management considers accident prevention as of great importance in the line with any another phase of operation or administration. Therefore, its is the policy of the company to provide and maintain safe and healthy working environment and to follow operating practices that will safeguard all employees and result in safe working conditions and efficient operations.

Each employee has an individual responsibility to follow safe practices and to detect and report hazardous conditions to his/her superior. All of us ensure the working conditions at the factory to be clean, orderly and safe.

Mission

Customer satisfaction is earned by products of zero defect meeting international quality standards. Competitive edge is strengthened by continuous R & D efforts for improving existing process and innovations to broaden the product mix.

Future plans

The Company plans to expand in intermediates and dyes mainly based on own research and development efforts. The Company proposes to strengthen manufacturing base and thrive for quality as its motto.

Quality control testing facilities

The Company has established well-controlled system for day-to-day inspection and quality control through procedures, work instructions and quality plans, which cover total range of products manufactured by the company. The day to day quality control is controlled by senior chemists with use of appropriate calibrated instruments and gauges.

Connect with facebook

Connect with facebook Follow on twitter

Follow on twitter Sharing on Google+

Sharing on Google+ Videos on YouTube

Videos on YouTube Connect with linkedin

Connect with linkedin